Perfect Metal Coating for Machines and Devices

In today’s competitive manufacturing landscape, the need for precision and quality is paramount.

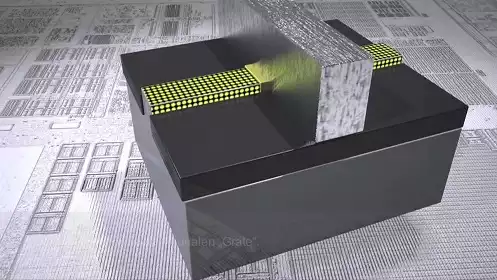

As you explore innovative solutions to enhance your production processes, consider the capabilities of a 750W Plasma Surface Treatment Machine, the Perfect Metal Coating for Machines and Devices.

This advanced technology is designed to improve surface properties, enabling superior adhesion, wettability, and cleanliness across a variety of materials.

Whether you’re working with plastics, metals, or ceramics, the 750W Plasma Surface Treatment Machine can significantly elevate the performance of your products.

By harnessing the power of plasma, this machine effectively modifies surfaces at the molecular level, resulting in enhanced bonding for coatings, paints, and adhesives.

As you delve into the specifics of this machine, you’ll discover how its features can streamline operations, reduce costs, and ultimately drive your business towards greater efficiency and competitiveness.

With its versatility and effectiveness, the 750W Plasma Surface Treatment Machine not only meets the demands of modern manufacturing but also positions you for future innovations.

Join us as we explore the benefits, applications, and technical specifications of this cutting-edge equipment, empowering you to make informed decisions that will lead your operations to success.

Table of Contents Perfect Metal Coating for Machines and Devices

Activate surfaces with effective plasma treatment

When considering activation and coating treatments, utilizing plasma technology can significantly enhance surface properties for various materials, including cable, glass, and metal.

The process effectively cleans surfaces at a molecular level, removing contaminants and preparing them for improved adhesion of coatings or other functional layers.

By employing a rotating nozzle, the treatment ensures uniform coverage and optimal activation, making it ideal for intricate geometries and complex shapes.

With this method, you can achieve superior bonding characteristics, leading to enhanced performance in applications requiring strong adhesion and durability.

Surface plasma cleaning represents a cutting-edge solution to achieve desired surface characteristics without the need for harsh chemicals or extensive labor.

This technique not only streamlines your preparation process but also contributes to an environmentally friendly manufacturing practice.

By activating surfaces with precision, you can significantly improve the longevity and efficacy of coatings applied on your components, ultimately leading to enhanced product reliability and customer satisfaction.

Enhance coating treatment for durability

properties through plasma treatment, you can significantly improve the longevity and resilience of coatings applied to your materials.

The enhanced surface energy resulting from this treatment allows coatings to bond more effectively, reducing the likelihood of delamination, chipping, or wear over time.

As a result, you can expect better performance in demanding environments, thereby increasing the lifespan and reliability of your products.

Moreover, the use of plasma technology ensures that the coating treatment is not only swift but also precise, enabling you to target specific areas that require enhanced durability.

This tailored approach allows you to optimize your resources while minimizing waste, ultimately leading to cost-effective production.

By integrating advanced plasma activation and coating processes into your workflow, you can achieve a competitive edge in durability and surface performance, meeting the rigorous demands of modern applications.

Achieve optimal surface plasma cleaning

Utilizing advanced surface plasma cleaning techniques is essential for ensuring optimal performance and adhesion across various materials, including cable, glass, and metal.

By employing methods that enhance surface activation, you can prepare substrates to achieve a higher degree of cleanliness and reactivity, facilitating better bonding with subsequent coatings.

This meticulous attention to surface preparation not only elevates the quality of your final products but also ensures that they withstand environmental stressors, thereby enhancing overall durability.

The incorporation of a rotating nozzle system further amplifies the efficacy of surface plasma cleaning by providing uniform treatment across complex geometries.

This innovation enables you to reach intricate surfaces and achieve comprehensive cleaning, eliminating contaminants that could compromise adhesion.

As a result, you create a well-prepared substrate that maximizes the effectiveness of your coating treatment, leading to improved performance and longevity of your products in diverse applications.

By prioritizing effective plasma cleaning strategies, you set a strong foundation for superior surface treatment outcomes.

Suitable for cable, glass, and metal

When working with various substrates, such as cable, glass, and metal, achieving optimal surface activation and coating treatment is crucial for enhancing adhesion.

The unique properties of these materials necessitate a tailored approach to plasma treatment, ensuring that each surface is adequately prepared to receive coatings.

By implementing surface plasma cleaning techniques, you can effectively remove impurities and contaminants that may hinder bonding, ultimately leading to improved performance and longevity of your products.

The versatility of your treatment approach allows you to cater specifically to the needs of different materials.

Whether handling delicate glass or robust metal, the ability to adjust treatment parameters ensures that each surface receives the appropriate level of activation.

This adaptability, combined with the benefits of a rotating nozzle, allows for thorough coverage and consistent results, resulting in substrates that are primed for enhanced adhesion and superior coating application.

With these advancements, you can confidently tackle a wide range of applications, knowing that your surface treatment processes are optimized for success.

Utilize rotating nozzle for versatility

the application of coatings.

The rotating nozzle enhances your capability by providing a dynamic spray pattern, which ensures uniform plasma exposure across varied surface geometries.

This feature is particularly beneficial when treating complex shapes or intricate designs, as it mitigates the risk of inconsistent activation.

By incorporating the rotating nozzle into your process, you can achieve superior surface plasma cleaning, effectively addressing the challenges presented by different substrate types.

This level of versatility not only streamlines operations but also maximizes efficiency, enabling you to address the specific requirements of each material while maintaining high standards of quality.

As a result, your applications will exhibit improved adhesion properties and overall performance, contributing to the durability and reliability of your end products.

Improve adhesion with plasma activation

Plasma activation significantly enhances adhesion by modifying the surface properties of substrates such as cable glass and metal.

Through the precise control of activation and coating treatments, you create a reactive surface that promotes stronger bonding with subsequent layers of coatings or adhesives.

This meticulous process leads to superior adhesion outcomes, minimizing the likelihood of delamination and ensuring that your products perform optimally under various conditions.

Utilizing plasma activation allows you to tailor the surface treatment to meet the specific characteristics of your materials.

The advanced technology not only cleans the surface at a molecular level but also increases the surface energy, facilitating improved attachment of coatings or adhesives.

This strategic approach not only elevates the performance of your products but also enhances their longevity, making them more resilient to environmental stressors and mechanical wear.

Ensure thorough cleaning of surfaces

Achieving a high standard of cleanliness on surfaces is essential for optimal bonding and performance.

By employing surface plasma cleaning techniques, you effectively eliminate contaminants, dust, and residues that could hinder adhesion.

This thorough cleaning process is particularly critical when working with materials like cable glass and metal, where even minute impurities can compromise the integrity of the bond.

The use of a rotating nozzle allows for uniform treatment across various surface geometries, ensuring that every corner is addressed during the cleaning phase.

Incorporating these practices not only prepares the surface for subsequent treatments but also enhances the overall durability of the final product.

By addressing cleanliness at a molecular level, you bolster the effectiveness of any activation and coating treatment applied afterward.

This comprehensive approach guarantees that every application achieves the desired performance characteristics, leading to longer-lasting products that meet the demands of diverse operational environments.

Increase performance of coated materials

you can significantly enhance the performance of coated materials through meticulous surface preparation and treatment techniques.

By utilizing advanced activation and coating treatments, you create an optimal interface that promotes superior adhesion and resilience.

The combination of thorough surface plasma cleaning and effective coating processes ensures that the treated materials exhibit improved resistance to wear, corrosion, and other environmental factors.

Moreover, the strategic use of a rotating nozzle during the cleaning and treatment phases allows for even coverage and penetration, which is particularly beneficial for complex geometries often found in cable glass and metal products.

This attention to detail not only maximizes the adhesion of coatings but also extends the lifespan of the materials, making them more reliable for demanding applications.

By committing to these practices, you empower the coated materials to perform at their best, meeting and exceeding the stringent requirements of modern engineering and manufacturing standards.

Tailor treatments to specific applications

adapting to the specific requirements of various industries.

The effectiveness of your treatments can be further optimized by customizing the processes based on the unique characteristics of the materials involved.

For instance, when working with cable glass and metal components, you can adjust parameters such as plasma treatment time and intensity to achieve the desired surface properties tailored to each application.

By fine-tuning your approach, you ensure that the activation and coating treatments not only enhance the physical and chemical properties of the surfaces but also align perfectly with the performance expectations of end-users.

This level of customization allows you to tackle challenges specific to different applications, ensuring that the materials not only meet but exceed industry standards for durability and functionality.

Ultimately, your commitment to personalized treatment strategies positions you as a leader in providing high-performance solutions that are both reliable and effective.

Experience advanced technology in plasma treatment

Utilizing advanced plasma treatment technology significantly enhances your surface processing capabilities, particularly in the realms of activation and coating treatment.

The precision of surface plasma cleaning allows you to effectively remove contaminants and improve adhesion properties on various materials, ensuring optimal performance in demanding environments.

This is especially beneficial when dealing with cable glass and metal substrates, as the refined treatment enhances their durability and functionality.

Incorporating a rotating nozzle into your plasma treatment system enables uniform application across surfaces, maximizing the efficiency of the treatment process.

This innovative design not only enhances the consistency of the plasma exposure but also allows you to cover intricate geometries with ease.

By leveraging these advanced technologies, you can achieve superior surface modifications that cater to exacting standards, ultimately delivering enhanced products that fulfill and exceed market expectations.

In summary, the 750W Plasma Surface Treatment Machine represents a significant advancement in surface preparation technology, offering you enhanced efficiency and versatility for various applications.

By utilizing plasma treatment, you can improve adhesion, cleanliness, and overall surface quality, which is essential in industries ranging from manufacturing to electronics.

As you consider integrating this innovative equipment into your operations, remember its capacity to elevate your processes and yield superior results.

Embracing this technology can not only streamline your workflow but also position your business at the forefront of industry standards.